Red Tagging 5s, 5s Red Tags Qty 100 From Fabufacture Uk Fast Shipping Fabufacture Uk

Red tagging 5s Indeed lately is being sought by users around us, perhaps one of you personally. Individuals are now accustomed to using the internet in gadgets to see video and image data for inspiration, and according to the name of the post I will talk about about Red Tagging 5s.

- 5s Red Tag System Youtube

- Red Tag Holding Area Wall Sign Creative Safety Supply

- 5s Red Tag Register Form For Red Tagging Events Enna Com

- 5s Red Tags Verona Safety Supply

- 5s Red Tag Qty 300 Sku 6932 The Lean Centre

- 5s Red Tags Tag Board Lean Helper

Find, Read, And Discover Red Tagging 5s, Such Us:

- Red 5s Tags

- 5s Red Tags 100 Pack Lean Visual Management Enna Com

- Tpm Consulting Service Tpm Training Tpm Public Training Tpm In House Training Tpm Course Tpm Thai Training Tpm For Manager Oee Practical Tpm P M And Why Why Analysis Tpm Workshops Introduction To Tpm Tpm For Manager Practical Tpm

- Red Tag Holding Area Signs Banners Sku 6540 The Lean Centre

- 5s Red Tags

If you re searching for Oranje Leeuwinnen Mondkapje you've come to the ideal location. We ve got 104 graphics about oranje leeuwinnen mondkapje including images, photos, photographs, backgrounds, and much more. In such webpage, we additionally provide number of images available. Such as png, jpg, animated gifs, pic art, symbol, blackandwhite, transparent, etc.

The red tag strategy is implemented in the first phase or.

Oranje leeuwinnen mondkapje. If an item is necessary return it to a logical place. 5s audit checklist for the factory. This concept of ongoing improvement and working toward ideal efficiency is known as kaizen in lean circles which 5s is a part.

During the sorting step of 5s unnecessary items are removed from a work area. On the other hand if you determine an item is still needed remove the red tag and find an appropriate location to store it. 5s offers your production system an opportunity to evaluate its departments and find ways to speed things up cut out extra inventory decrease waste and get the.

5s red tag strategy implementation at your facility by jim redmile the 5ss are a continuous improvement methodology started in japan after world war 2 and mastered by toyota. The red tag is a useful tool to help the sorting process in the factory warehouse or office. Sometimes personal ties to specific tools and equipment can stand in the way of the sorting phase of 5s.

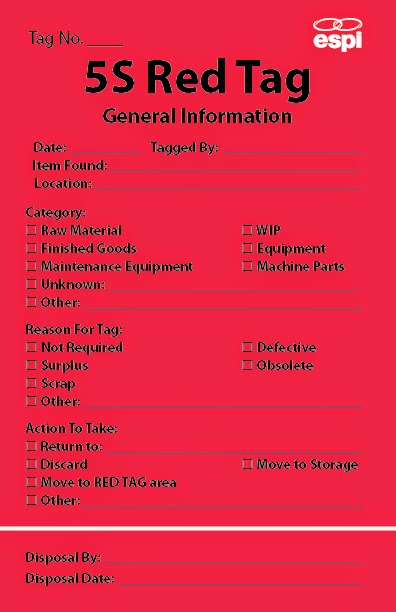

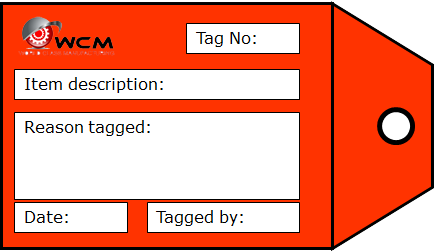

These tags are used to identify unnecessary items that need to be either thrown out recycled sold or relocated. Incorporate the 5s steps into the business. Because teams are often created ad hoc there is the potential for someone to inadvertently remove an item that is actually needed for production.

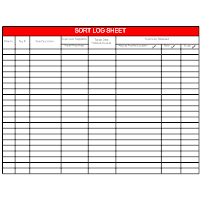

They stay in this area for a specified period of timeoften a month or twoso you can determine whether theyre necessary or can be removed recycled or given to other departments that might need them. Designed to be used with our 5s red tag register an 1114 pad of forms that logs all items identified by red tagging. 5s red tag packs 5s red tags are used to keep the process of change going throughout the 5s workshop while remaining organized in the process.

As an aspect of the sorting process of 5s a 5s red tag system has long been popular. When someone is placed in charge of the red tagging strategy they can eliminate accumulation and keep items moving in the right direction. Understanding 5s in the workplace.

5s red tags are used for visual management of a workspace clearly marking items that need to be moved creating workplace organization. 5s red tagging items are often placed in a separate location called a red tag area. 5s red tag sample if your company has embarked on starting a lean program to improve its bottom line it is a very advisable that you will be implementing 5s into the workplace.

When transliterated from the original japanese the 5ss stand for sorting setting in order shining standardizing and sustaining the discipline. For more information or to purchase 5s. Tools for each s in 5s.

The red tag process is closely tied to the sort step of the 5s process. How lean and 5s can improve the. 5s red tags a useful sorting tool the red tag is a useful tool to help the sorting process in the factory warehouse or office.

Visual safety begins with 5s.

More From Oranje Leeuwinnen Mondkapje

- Nottingham Forest Jersey

- Unesco Global Geopark

- Alejandro Dolina Frases Politica

- Rozal

- Debate Club Genshin Impact

Incoming Search Terms:

- 5s Red Tag Strategy Business Building Information Debate Club Genshin Impact,

- 5s Red Tags Hanging Tags Lean Helper Debate Club Genshin Impact,

- 5s Red Tag Station Kits Seton Debate Club Genshin Impact,

- 5s Red Tag Holding Area Silver Sku 9313 The Lean Centre Debate Club Genshin Impact,

- 5s Red Tag Template Tag Template Templates Tags Debate Club Genshin Impact,

- 5s Red Tag Station Visual Management Dental Supply Organization Lean Manufacturing Debate Club Genshin Impact,